How UltiMatham works?

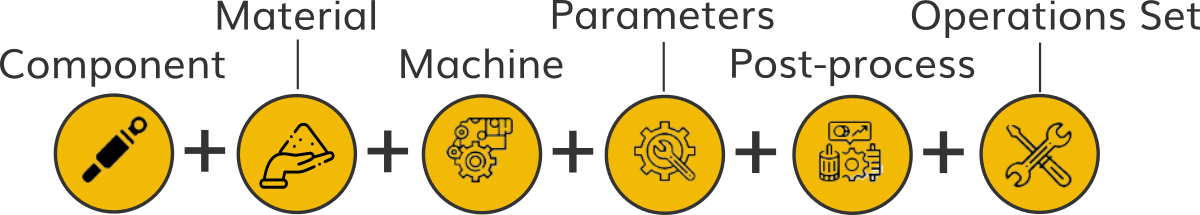

An accurate cost calculation for Additive Manufacturing relies on several input variables. The specifications of your part are the starting point. How big is its bounding box? Which is its total volume and the total surface/volume ratio? What is the scope of the component (aesthetic, structural, and so forth). Those parameters are possibly the most important ones since they define the boundary limits of your manufacturing space. From there, the material, the equipment, the process parameters, the post-processing options and the overall operation setting you'll run will all affect the cost and quality output of your 3D printed component.

UltiMatham is a tool that provides you with a preset database counting hundreds of certified records. All technologies are represented (i.e., AM equipment) and for each of them you'll find appropriate process, post-process, material and so forth. While the scheme looks pretty simple, the variables UltiMatham takes into account are more than a hundreds for each calculation. Additionally, the software gives the opportunity to modify each of those parameters, to create a unique setting (e.g., your current or future AM shop floor). Once the calculation run, you'll be prompted with interactive and detailed charts, as well as a professional written report containing all analytics you'll need.

Components used to create your industrial cost. Each of them embeds dozens of variables, that combine together to give an accurate preview of your cost.

A bunch of additional features enrich the platform, such as the ability to run a quick technology comparison or the option to compare whatever item you have created: you can compare cost calculations, materials, parts, equipment and everything you wish. The comparison relies on detailed data plotted on interactive chart, and will empower you to understand AM cost dynamics easily and hassle-free. Last but not least, the software runs a series of cross-checking task that will give you hints and tips about the choices you made as well as errors checking. For instance, if a part is too big for a given equipment the calculation run will prompt you about the issue. More interestingly, the specification of each dataset (e.g., a part complexity vs a technology capability, or a part's surface look requisite against a give post-processing expected output) is checked to ensure you are making coherent choices. The algorithms that power this smart engines are able to predict the success rate of your print, giving you not only the cost per part but a full set of suggestion to make your project a success.